Wedge Wire Screen - V Wire Slotted 304 and 316 Mesh Filters and Sieves

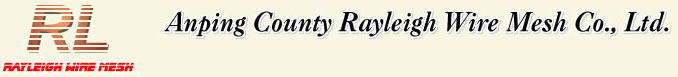

Wedge Wire Screen also known as Profile Wire Screen, V Wire Screen, Slot Screen, is made by wrapping v profile wire cylindrical around longitudinal placed support rods through electric resistant welding process. Wedge wire screen in stainless steel 304 and 316 offering chemical and thermal resistance is used for liquid, gas and solid separation, sizing, dewatering and sifting in oil wells, water wells and the chemical industry. Steel alloys are also used in wedge wire materials for specific requirements. According to applications, Wedge Wire Screen is divided into Wedge Wire Filters, Wedge Wire Cylinder, Sieve Screen, Sifting Screen, Well Screen ( Oil Well Screen, Water Well Screen), Intake Screens.

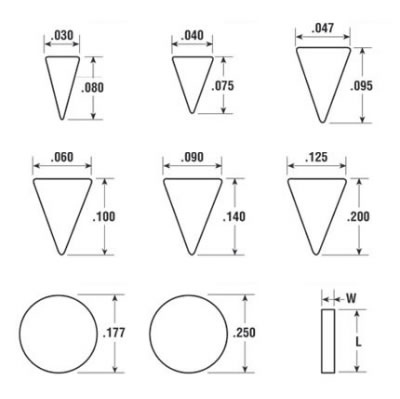

We supply wedge wire screen in numerous combinations of wires and support rods, top styles:

The numerous combinations of profile wires and support rods, and the wide range of apertures between the wires and rods allows innovative designs of filter screen to meet specific technical requirements.

The wire screen is supplied in various wire diameter, slot size, panel thickness and length.

Many screen forms is supplied: Flat wedgewire panels, curved wire mesh sieves, wedge wire cylinders, tubes and baskets, filter elements.

Wedge Wire Top Profiles: Flat, Conical, Square

For coal industries, flat top wedge wire is an ideal choice, it is a high efficiency screening material for the de-watering of slurries and is extensively used in coal washers.

For fine mesh filtrations, conical top wedge wire is particularly designed for de-watering slurries with fine filtration requirement.

For large aperture filtration system, square top wedge wire is the right choice.

Consult us if you are not sure how to choose and we are glad to help.

Wedge Wire Benefits:

Accurate filtration: Wedge wire mesh has precise and continuous slot openings resulting in accurate separation without loss off media.

High efficient process:

V-shaped profile wires offer continuous slots openings which enlarge inwardly and therefore avoid clogging and minimize downtime.

High strength:

The screen is fabricated by circumferentially wrapping a wire around a circular internal core of longitudinal rods with each intersection between wire wrapping and support rods and securely welded. The all-welded stainless steel construction produces a high strength and extended service life suitable for many screening applications in numerous industries.

Corrosion resistance: The stainless steel wedge wire has excellent anti corrosion, anti alkaline, anti acid property.

Low maintenance: Wedge wire can be easily cleaned by scraping or back washing.

Low cost: Wedge wire filter elements can be assembled easily and re-used repeatedly.

We produce and export following wedge wire well screen, sieves and filter elements:

Stainless Steel Well Screens, Wedgewire Profile, 600' Collapse Depth, 1200' Depth

Well screen 16" diameter wire wrapped, continuous slot, 304 stainless steel with the various slot widths is popular wedgewire product. Commonly supplied stainless steel well screen are designed for two maximum collapse depths:

1. Shallow Well Screen, with a Collapse depth of 600 feet

2. Deep Well Screen, with a Collapse depth of 1200 feet

Details:

16" Diameter, 304 Stainless Steel, 0.010" Slot Screen, collapse depth of 600’

16" Diameter, 304 Stainless Steel, 0.020" Slot Screen, collapse depth of 600’

16" Diameter, 304 Stainless Steel, 0.030" Slot Screen, collapse depth of 600’

16" Diameter, 304 Stainless Steel, 0.060" Slot Screen, collapse depth of 600’

We supply stainless steel well screen with 6" weld rings on both ends with a 16” type 304 stainless steel weld collar attached to one end.

Slot openings shall be clean and free of burrs.

Well screens are fabricated from corrosion resistant type 304 stainless steel, cold drawn or cold rolled, wire or bars meeting the requirements of ASTM A493-09 (2009).

Wire wrapping is wedge shaped with the narrow end welded to the longitudinal rods.

Well screen furnished in nominal 10-foot and 20-foot lengths.

Well Screen Fittings and Accessories:

The end fittings for the supplied well screen are Type 304 stainless steel with 6" weld rings on both ends and have the minimum length required for adequate strength at the joints between the screen sections.

End fittings machine beveled for ease of insertion into stainless steel collar.

Individual 16” diameter type 304 Stainless Steel collars.

Wedge Wire for Screens, AISI 316

Wedge Wire Type 34

Slot width 3mm

Max. water difference across screen area 1,5 m Water

Material AISI 316TI / AISI 316

Screen field area 38 m2 / screen (B=3,8m x H=10m)

Mounting dimensions:

Width (3,8m) - Channel width

Height 1-3m - each field

Frame construction varies.

Standard Wound Wedge Wire Screen 316L SS

External diameter: 50mm;

Wire #60

Plain square ends;

Length - per 2 metres each;

Slot size - 0.4mm and 0.2 mm

Material - 316/316L S.S.

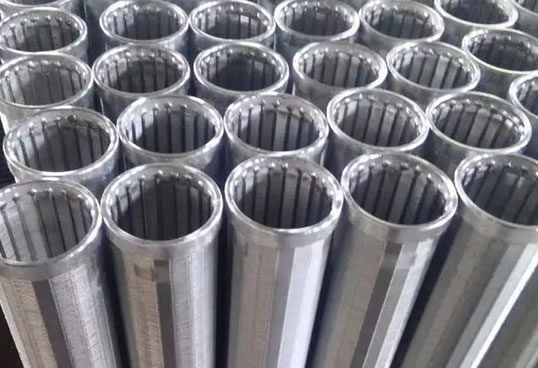

Standard wounded V wire structure for Outside In Filtration, as shown following:

Flow Outside In

Standard Wound

Reverted wire wrapped wedgewire for Inside Out Flow Filtration, as shown following

Flow Inside Out

Inverted Wrap

Wire types:

Wedge Screen Filters, SS304

Stainless Steel Wedge Type Screen Filters with the following specifications:

| Thickness of wedge wire | 0.60mm |

| Width of wedge wire | 1.80mm |

| Spacing between two wedge wires | 1.2mm |

| Effectivce length | 400mm |

| Effective diameter | 29mm |

| Wedge wire inside diameter | 25.4mm |

| Wedge wire outside diameter | 29mm |

| Material | SS-304 |

| Uses | Filter elements |

SS 304L Wedge Element for Backwashing

Filter Element Size (mm) : 90 Dia x 1000 Length.

Flow Direction : In to Out in normal flow

Material : SS 304L

Size of Opening : 25 microns

Wedge Wire Screen Flat Panels for Electro Static Sieves:

Panel width: 383mm+/-2mm; or 483mm+/-2mm

Length: Maximum Length Possible

Load: Maximum 4.5kg / square cm

Slot Opening: 5mm

Support profile: Flat bar

Material: S.S. 316 / S.S.316L

S. S. 316L Mesh Filters Wedge Type, for water well filtration and oil well filtration

Dia of Mesh filter is 60.3mm x 1070 mm length

Dia of Mesh filter is 60.3mm x 470 mm length

Wedge Type Filter Elements Sizes:

Filter element wedge type of 152 O/D; 50 micron; length 805 mm; Material SS 316; Designed for outside to inside filtration at work pressure 10 kg / cm2;

Filter element wedge type of 100 O/D; 150 micron; length 875 mm; Designed for out to in filtration at work pressure 21 kg / cm2;

Filter element wedge type of 100 O/D; 150 micron; length 450 mm; Designed for out to in filtration at work pressure 21 kg / cm2;

Filter element wedge type of 100 O/D; 100 micron; length 745 mm; Designed for out to in filtration at work pressure 42 kg / cm2;

Filter element wedge type of 25 O/D; 150 micron; length 250 mm; Designed for out to in filtration at work pressure 30 kg / cm2;

Filter element wedge type of 60 O/D; 150 micron; length 245 mm; Designed for out to in filtration at work pressure 10 kg / cm2;

Filter element wedge type of 60 O/D; 50 micron; length 1000 mm; Designed for out to in filtration at work pressure 40 kg / cm2.

SS Screen Wedge Wire Cylinders

Type: Flow - in to out

Smooth internal surface finish

Vertical slots to 25, 50, 75, 100, 200, 400, 600 microns

Outside ribbings circularly on the periphery

Cylindrical tubes supplied in sizes:

8” dia x 24” long – area 610 sq inches

7” dia x 12” long - area 264 sq inches

3.25” dia x 12” long – area 112 sq inches

Maximum pressure drop across screen : 110 psid

Type: Flow - out to in

Smooth outersurface finish

Vertical slots to 25, 50, 75, 100, 200, 400, 600 microns

Inside ribbings circularly on the periphery

Cylindrical tubes supplied in sizes:

2” dia x 12/24/36”

3.25” dia x 12/24/36”

Maximum pressure drop across screen : 110 psid

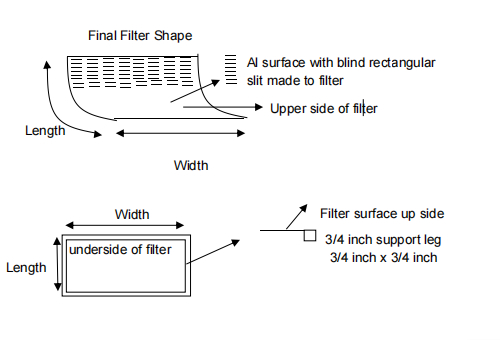

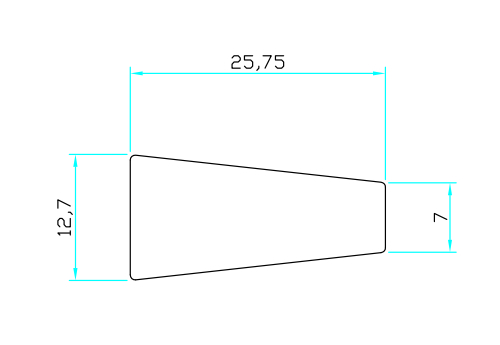

Final Filter Shape Illustrations:

Al surface with blind rectangular slit made to filter

Wedge Wire Filter Elements

Stainless Steel Wire Packed Well Screen from Inside to Outside Filtration

Length: 1100mm

Diameter: 192mm

Micron range: 10-25 micron

Up side and bottom side are open

Filtration: from inside to outside

Material: ss316 stainless steel

Wedgewire filter elements are used as sieves and filters for various industries, filter component fabricated from v wire.

Grinder wedge wire screen bar:

SS304 Wedge Wire Curved Panel - Sieve Bend Screening Unit - Dewatering Screen

Wedge wire sieve screening for de-watering, sizing, and wastewater cleanup problems.

For food processing, malting, floor grating, ventilating systems.

Material:stainless steel 304, 316

Slot:0.05-50mm.

Size: 1005mm wire x 727mm arc length

Wire profile: 3.3 mm x 6.35 mm

Rod support: 3 mm x 6.5 mm

Slot: 0.6mm

Radius: 225mm

No end bars

Meterial: SS304

2.5 mm slot opening flat sieves is popular for supporting fine filter media.

Materials of Screens in SS316L.

Drum dimension 1800 x 6000 mm

Gap : 0.7 mm

Download Wedge Wire Metal Mesh Technical Reference PDF Files:

Wedge Wire Screen Cylinder for Filters

Wedge wire slotted screen, inside to outside flow filter element, is easy for cleaning, due to the easy and quick disassembling from the filter system. It is cleaned by reversed flow at certain conditions.

V Wire Back Wash Filter Element

Inside to Outside Flow Back wash filter for industrial water treatment. Drainage pipes, designed for max. working pressure of 10 bars, with a filtration rating of 100micron and 200microns.

Perforated Wedge Wire Slot for Well Screen Filtration

Perforated Pipe + Wedge Wire Slot for Well Screen. Wedge Mesh and Perforated Tube are fully accessible, manufactured by corrosion resistance stainless steel and alloy steel.

304L Wedge Wire Screen for Reactors

V Shaped Wedge Wire Slot Screen, supplied with rings and flange. It is made of 304L stainless steel wire, which is the most popular type because of outstanding chemical stability and corrosion resistance. Tube diameter: 650 mm. Tube length: 1850mm, 1950mm, 2700mm, other sizes.

Stainless Steel 316L Wedge Wire Wrap Screen

V Wire Wrap Screen: Stainless Steel SS 316, 316L

Slot Opening: 0.177mm. Wrap wire or wounded wire.

Stainless Steel Mesh

- Dutch Wire Mesh

- Stainless Steel Wire Mesh Panels

- Stainless Steel Wire Rope Mesh

- Stainless Steel Insect Screen

- Stainless Steel Architectural Mesh

- Micron Stainless Steel Wire Mesh

- Extra Wide Stainless Steel Wire Mesh

- Stainless Steel Knitted Mesh

- Stainless Steel Filter

- Stainless Steel Thin Wire

- Stainless Steel Fine Wire

- Stainless Steel Chicken Wire

- Stainless Steel Welded Wire Mesh

- Stainless Steel Wedge Wire Screen

- Stainless Steel Hardware Cloth

- Stainless Steel Square Wire Mesh

- Stainless Steel Wire Mesh Machine

- Stainless Steel Wire

- Silver Brazing Stainless Steel Wire Mesh

- Stainless Steel Wire Mesh

- Stainless Steel Decorative Wire Mesh

- Stainless Steel Crimped Wire Mesh

- Stainless Steel Conveyor Belt

- stainless steel thin mesh

- stainless steel sintered mesh

- Stainless Steel Wire Mesh Shelves

- Stainless Steel Wire Mesh Baskets

- Stainless Steel Perforated Metal Mesh

- Stainless Steel Hexagonal Wire Mesh

- Stainless Steel Sheet/Plate

Other Wire Mesh

Email: sales@stainlesssteelwiremesh.us URL: https://www.stainlesssteelwiremesh.us